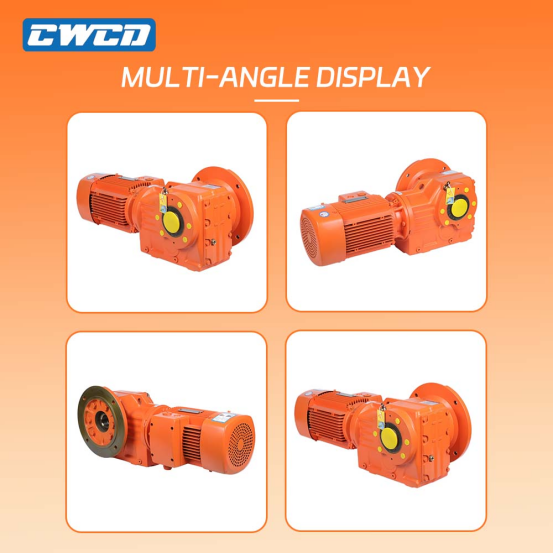

Factory Custom High Efficiency K Series Hard Face Helical Gear Reducer with Output Flange

-Brand Name:CWCD

-Gearing Arrangement: Helical

-Output Torque:1.8-2430N.M

-Input Speed:o-1500rpm

-Output Speed:0-180rpm

-Gross weight:14KG

- Overview

- Recommended Products

Product Overview

K Series Helical-Bevel Gear Reducer is a high-performance power transmission solution designed for industrial applications requiring high torque, compact structure, and precise motion control. By combining helical gears and bevel gears, this series achieves efficient torque transfer with optimized space utilization, ensuring reliable operation even in harsh working environments.

Key Features:

High Efficiency up to 96%

Precision helical-bevel gear design reduces energy loss, maintains stable transmission, and improves system productivity.

High Torque Density & Compact Structure

Reinforced gear housing ensures strong load-carrying capability while minimizing installation space.

Wide Range of Models & Ratios

Ratio: 8 – 5000, fulfilling diverse application requirements.

Flexible Installation Options

Foot mounting / flange mounting / shaft mounting available.

High-Strength Materials

Gears made from carburized and hardened alloy steel for long service life.

Low Noise & Smooth Operation

Precision machining ensures reduced vibration and quieter performance.

Modular Combination Design

Easy integration with motors, couplings, and other drive components.

Product name |

Factory custom high efficiency K series hard face helical gear reducer with output flange |

Model Number |

K47 KF47 KA47 KAF47 |

Place of Origin |

Jiangsu,China |

Brand Name |

CWCD |

Gearing Arrangement |

Helical |

Output Torque |

1.8-2430N.M |

Input Speed |

o-1500rpm |

Output Speed |

0-180rpm |

Gross weight |

14KG |

Customization Options

We provide flexible customization to meet your specific requirements:

·Input flange and motor type (IEC / Servo / Stepper)

·Output shaft shape and size

·Special surface treatment (anti-corrosion, paint color, etc.)

·Sealing options for dust-proof or water-proof use

·Customized ratio and torque range

·Private label & OEM branding

It is widely applied in various mechanical equipment fields, including environmental protection engineering, printing and dyeing chemicals. Warehousing and logistics, beer and beverage production, lifting and conveying, metallurgy and mining,tobacco and light industry, stereoscopic garages, rubber and plastics processing, road machinery packaging machinery, textile machinery, ice-making machinery, stage equipment, construction, enamel, ceramics, and more.

Founded in 2015,we are a manufacturer specializing in the production of gear reducers.

Changwei Transmission(Jiangsu)co.,ltd. is a company engaged in the manufacturing and sales of gear reducers, as well as the technological development and transfer of electrical machinery. We also deal in the sales of electronic products, electromechanical equipment,general machinery equipment, and their components.

Our main business scope covers products such as gear reducers, worm gear reducers, continuously variable transmissions(cvts),screw jacks, micro ac/dc gear motors and cycloidal pinwheel reducers.

Product quality and enhancing customer satisfaction are our core values. We will continue to upgrade our products and services striving for professionalism in every single item we produce and regularly evaluating customer satisfaction levels. This is not just a slogan; it has been deeply ingrained in every decision and action we take.

Q1.Can l obtain samples?

Yes.

Generally, we use our own factory nameplate with accompanying instruction manual and certificate of conformity. lf you need a special nameplate, please communicate in advance.

Q3. Do you have a factory?

Yes, we have a factory in Changzhou, Jiangsu. Covering an area of over 1200 square meters, welcome to visit our company and factory. We are a professional manufacturer that provides gearbox services to customers.

Q4. What is the production capacity of your factory?

Our production capacity can provide around 200-300 gearboxes (standard parts) per day. Nonstandard products are produced according to specific circumstances.

Q5.When will the shipment be made?

The general standard gearbox delivery time is 3-5 days. lf the quantity is large, we will communicate with you in advance based on the actual situation.